Insulation materials are subjected to long-term external electrical stress, resulting in a gradual decline in various properties called electrical ageing of the material. Many factors contribute to ageing, such as conductive currents, dielectric losses

electromagnetic forces, partial discharges and many other factors. However, as reflected in the current practical application, the main influence on the electrical ageing life of the material is the partial discharge, which is caused by the fact that in the manufacturing process

This is due to the fact that the manufacturing process contains a part of the air gap or other impurities that are easier to break down than the insulation medium, and when the applied voltage rises, this part of the air or other components cause local breakdown and local discharge.

Partial discharges are very damaging to insulation materials, but the process of partial discharge damage to materials varies from material to material due to different material structures, e.g. polyethylene is used in the manufacture of high voltage cables.

For example, polyethylene is used in the manufacture of high-voltage cables, where partial discharges cause accelerated cracking, and mica insulation for generator coils, where increased ion bombardment is considered the main cause of damage. The breakdown field of the material under discharge conditions is generally used to assess the electrical ageing parameters.

The breakdown field strength of the material under discharge conditions is generally used to assess the electrical ageing parameters.

Local discharges always leave irreversible traces of damage during the destruction of insulating materials and reflect obvious changes in the dielectric and mechanical properties of the material.

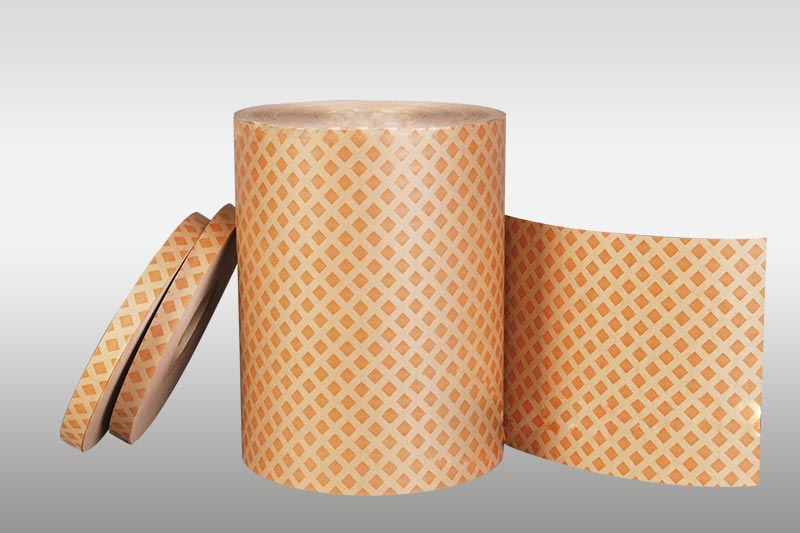

(1) The low molecular polar substances or acids generated by the discharge penetrate into the material, causing the volume resistance of the material to drop and the loss angle tangent to rise; such changes are particularly evident in oil-based paper insulation.

(2) Loss of elasticity, brittleness or cracking of the material.

(3) Gases and ions are left behind after the discharge, so that the material discharges from a gradually decreasing voltage, changing the various discharge characteristics.