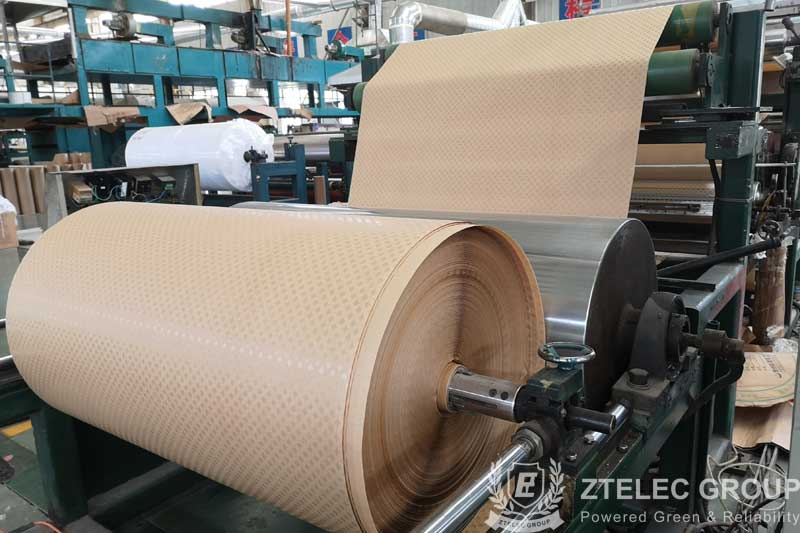

Winding insulation paper diamond dotted paper is widely used in power transformers,which can better ensure the long-term mechanical and electrical properties of the insulation structure.

The feature of the diamond dotted paper is that the coating layer begins to melt at a certain temperature in the drying process of the coil, resulting in adhesion, which can better ensure the long-term mechanical and electrical properties of the insulation structure.

Since the end of last year, ZTelec Group has been making efforts to upgrade the ddp paper, and now we have completed this project. The winding insulation paper ddp paper produced by our company has better adhesion ability to prevent the displacement of each layer of winding when short circuit;

The longitudinal insulation of power transformer includes three parts: inter-turn insulation, inter-layer insulation and inter-segment insulation. In the design of longitudinal insulation, we need to consider the various voltages acting on the longitudinal insulation and their gradient distribution; Technology during the power transformer winding manufacturing process; The interaction between windings in special cases; The influence of longitudinal insulation on the main insulation, the effect of the gap size on heat dissipation and so on. We should also consider these aspects:

1. Insulation between turns. The windings of oil-type power transformers are generally wound by diamond dotted paper. Because ddp paper is used as the turn insulation of power transformer windings, the dielectric constant of ddp paper is not much different from that of oil, the electric field distribution can be more uniform. However, we should also pay attention to the fact that the insulation thickness of the turn can not be selected according to the data of complete breakdown of oil gap.

2. Insulation between layers and sections. Interlayer insulation is mainly used for cylindrical windings. When the working voltage between the two layers is higher, the insulation between the layers must be thicker, which not only increases the radial size of the power transformer winding, but also is not conducive to heat dissipation, so that the temperature of the power transformer winding rises.

3. Oil type power transformer longitudinal insulation structure: Power transformers up to 35 KV; Total insulation of power transformers above 110 kV.

It is understood that the continuous development of insulation technology of power transformers at home and abroad, the oil channel between the power transformer windings has been continuously extended to six millimeters below. The winding height of power transformer is reduced, and the technical and economic indexes of power transformer are improved accordingly.